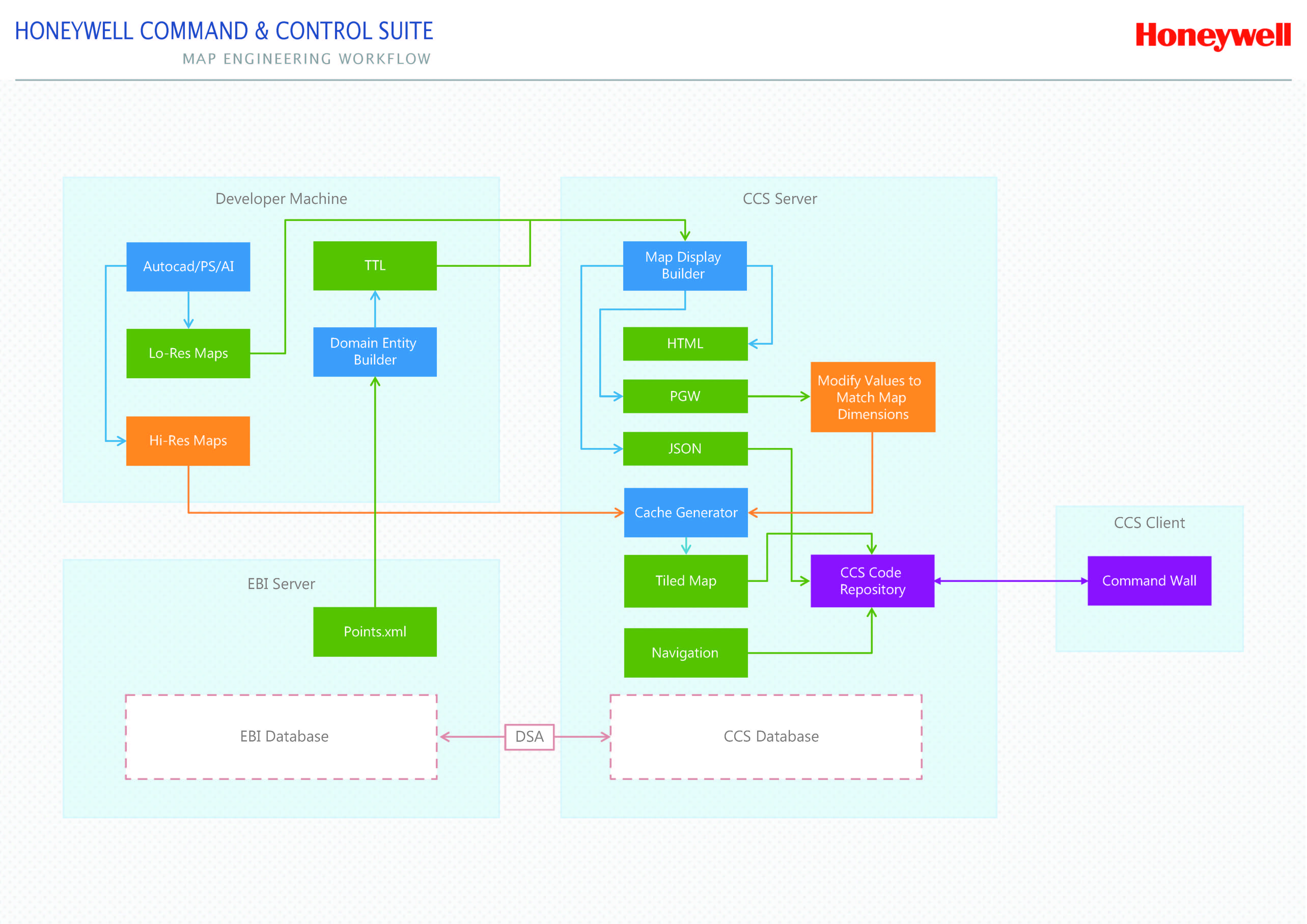

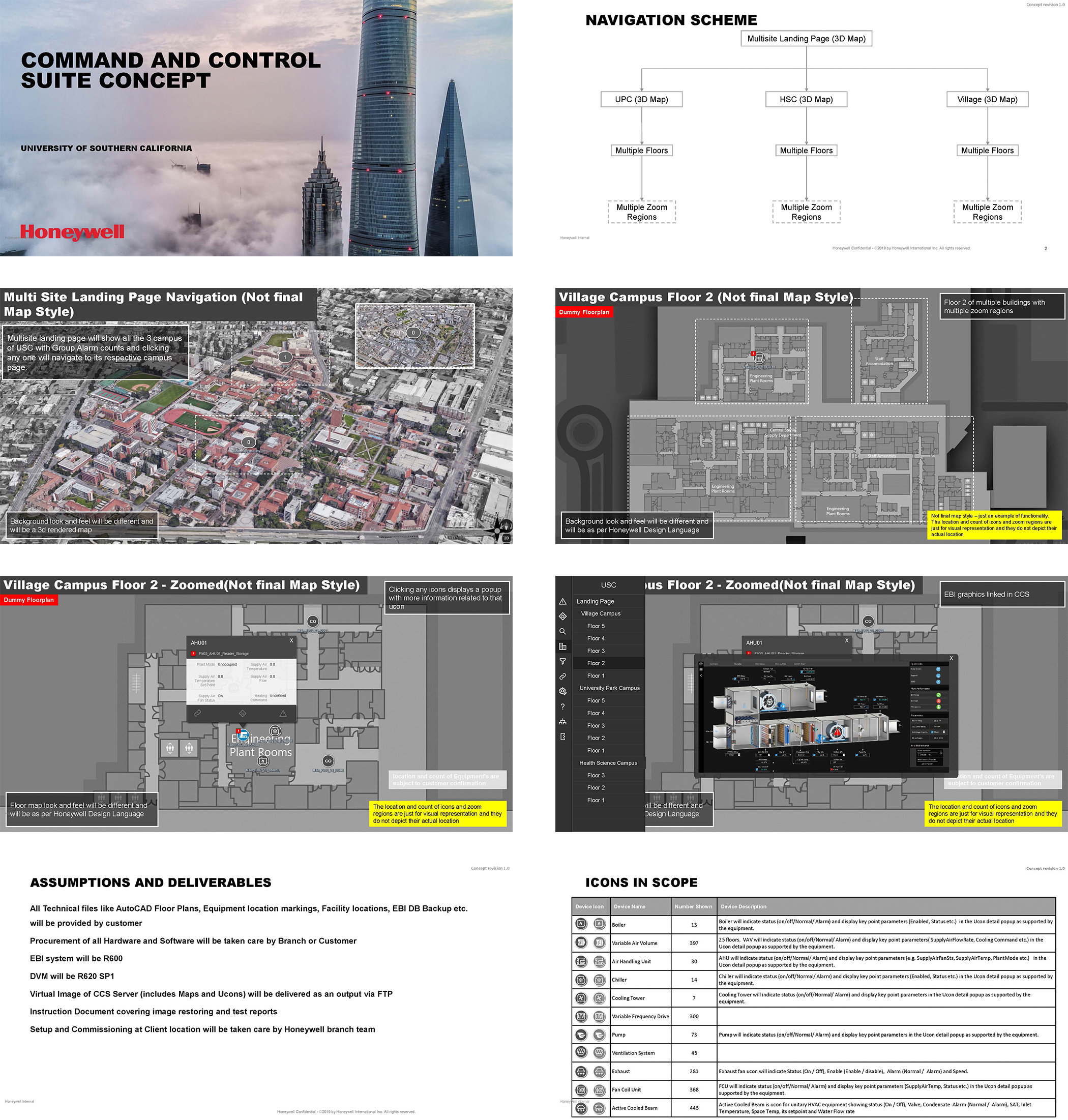

CCS was a newly developed product that will overaly on EBI and streamlines complex operations by coordinating systems, teams, and devices, even across distributed facilities. CCS is a suite of applications for diverse interfaces (desktops, laptops, tablets, wall-mounted touchscreens) designed to facilitate enterprise operations from virtually anywhere.

I was one of the first recruits in the CCS team for GES back in 2014. I understood the product, how the solution needs to be designed and developed, Set up the team and the complete work process to execute jobs from across the globe. All CCS jobs across the globe are designed and developed by GES.

I recieved product training from the development team in Sydney for both Designing and development. I understood the entire process of how CCS works, the do's and dont' of it, why CSS, the Sales process, role of GES and so and so forth. The version of CCS back then was R100 and now its R300.

Once I was back from the training the immediate task were to setup the team and get the hardware in place. Since CCS was a niche product, the requrement for resource as well for hardware was niche :). Based on the work forcast 4 designers and 4 engineers were planned to be recruited. Engineers we got from exisitng GES team, but for designers we have to get people from outside. Lot of interviews were conducted, we even went to neghbouring cites to get the right candidate.

Parallel with hiring process, I was working on procurment of hardware for Designers and Lab. Since designers had to work on generating maps of very large size, they needed high end laptops and this was the first time in GES we were ordering specific ones and not using the standard laptops provided by IT. We also had tough time to get the 65" touch screen monitor, as these were not introuduced in India back then.

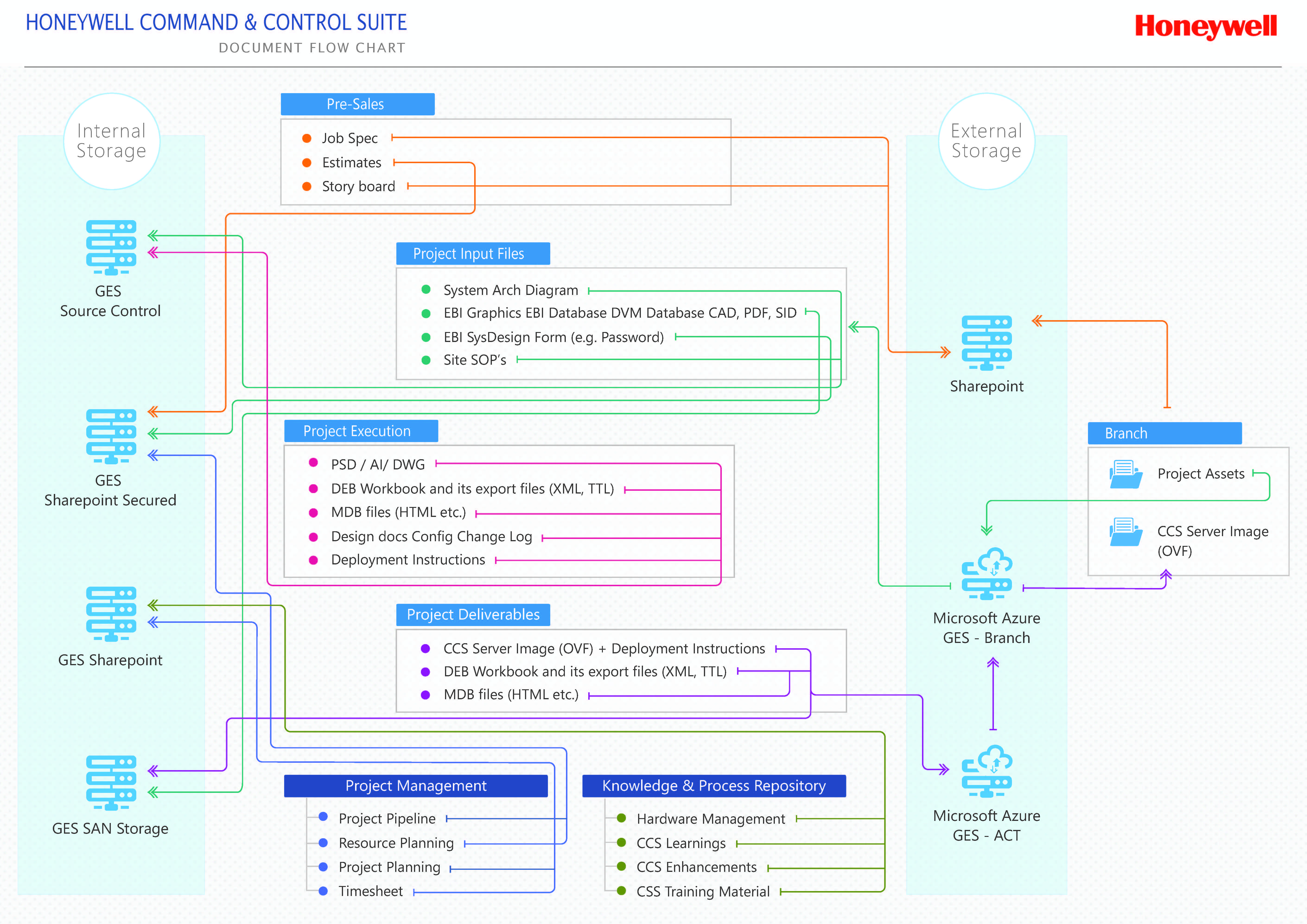

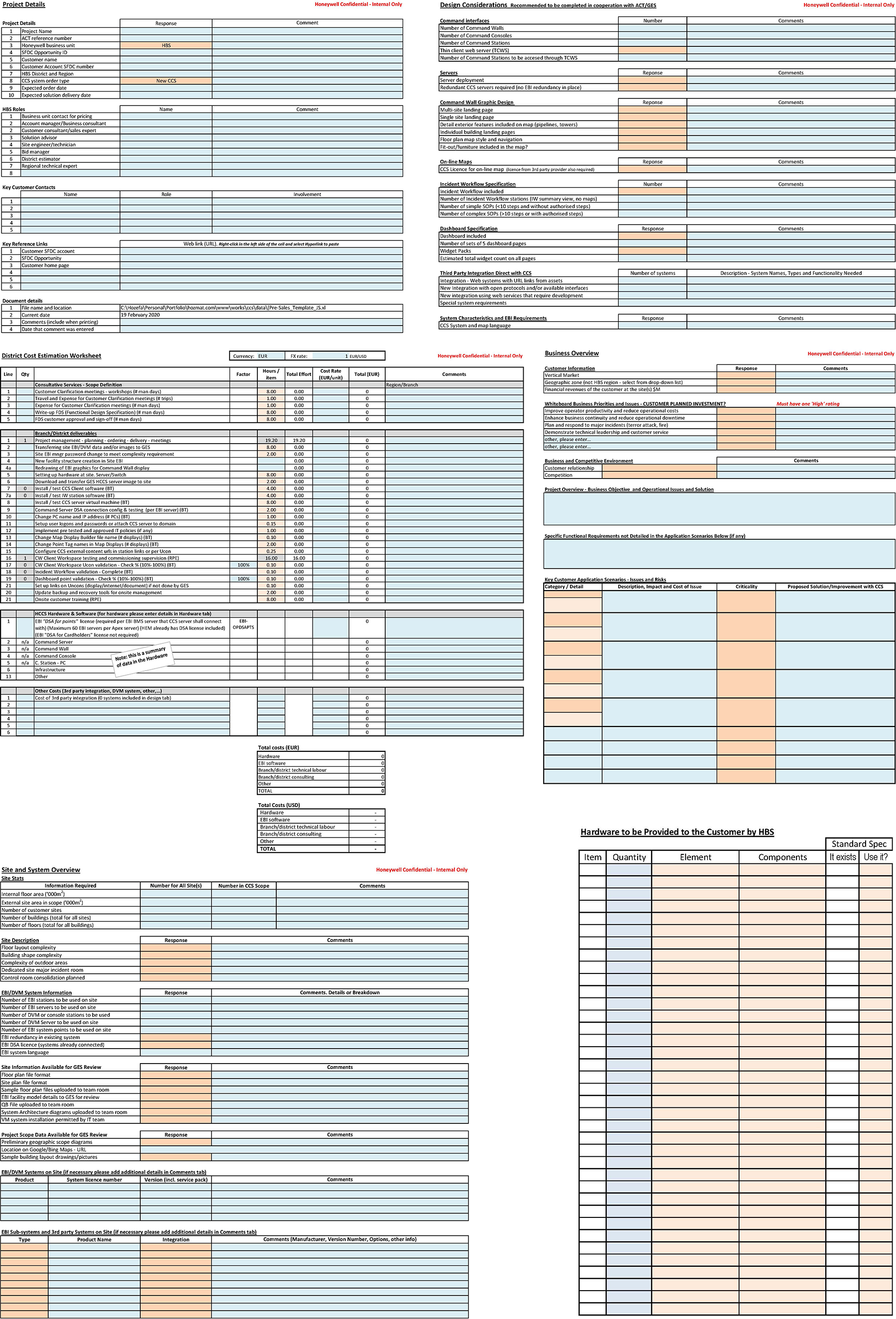

Once team and hardware was in place, the next major step was to set the work process starting from Pre-Sales to Post Delivery. I led this task, the entire CCS process along with all its checklists, documents and storage locations were finalized in consulatation and agreement with multiple stakeholders from ACT & GES management team.

For GES, Pre-Sales is the first step where it get's involved in the entire CCS process. Since this was a new product and to make know the product and its UPS's to clients and to give and guide them to an effective solution was my primary responsibilty along with managing the Map UI work.

Below are the 3 key documents/templates created for the pre-sales process. These were perodically updated to liase with new features in CCS.

- Job Spec - Scope Capturing Document

- Storyboard - Solution of the Scope

- Estimates - Design and Engineering Efforts

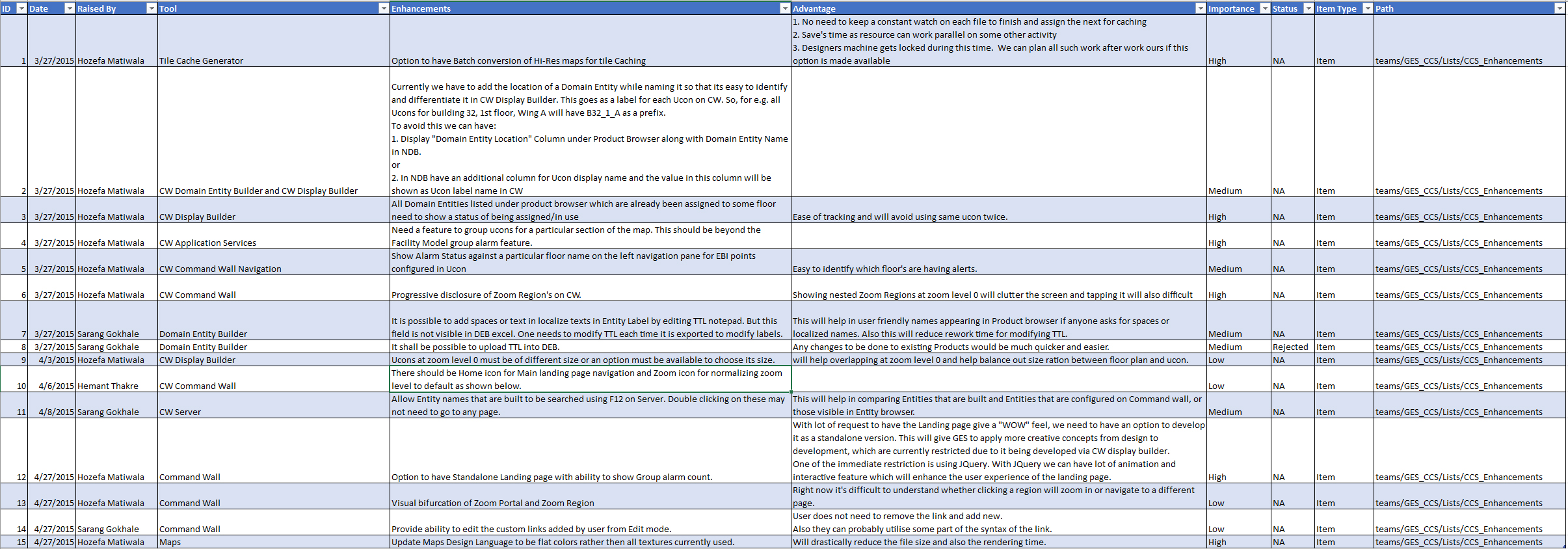

As GES was customer facing, and were using the tool to create customized solution to various customers globally they got the first hand information about the pro's and con's of the product. These were all captured and periodically shared with the product development team, which are periodically included in the product upgrades. Recent updates include

1. Updating Ucons on live system

2. CMT (Content Management Tool)

3. Google Map Integration

4. Product locator on Google Maps

Since inception till date GES has delivered approx 54 Projects and are going good. The product has gradually grown year after year and the current version is R300. Now CCS is a known name to all the honeywell branches globally and GES is supporting them well by delivering the work on time and with qaulity. The Current team strength is 12 Resources.